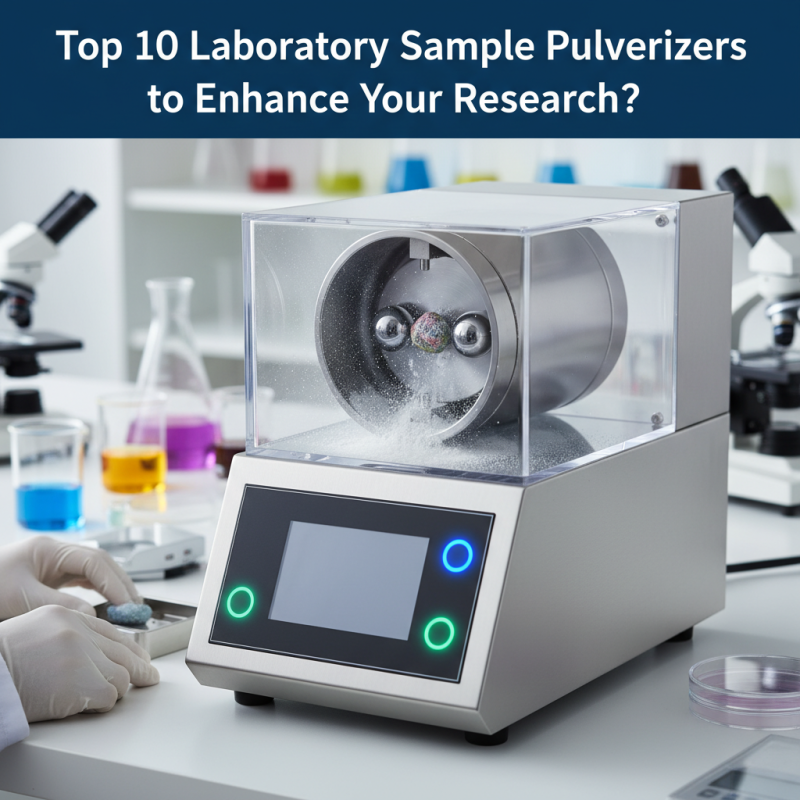

Top 10 Laboratory Sample Pulverizers to Enhance Your Research?

In the world of research, precision and accuracy are essential. A laboratory sample pulverizer plays a crucial role in achieving these goals. Researchers rely on these instruments to prepare materials for analysis. They need reliable and efficient tools to ensure data integrity.

Choosing the right laboratory sample pulverizer can be challenging. Different samples require different techniques. Some pulverizers are designed for softer materials, while others handle harder substances. This variety can lead to confusion, especially for those new to the field.

Furthermore, it's important to acknowledge that not all pulverizers are created equal. Some may not perform as expected, leading to inconsistencies in results. Researchers must remain vigilant in their assessments. A careful selection process can greatly enhance research outcomes. Ultimately, investing in a quality laboratory sample pulverizer can foster better experiments and insights.

Overview of Laboratory Sample Pulverizers and Their Importance

Laboratory sample pulverizers play a crucial role in research and development. They help scientists and researchers prepare samples for analysis. A well-grounded sample ensures accurate results and reliable data. Studies show that variations in particle size can impact analytical outcomes. Consistency in sample preparation is key.

Pulverizers come in various types, each suited for specific materials. A universal approach may lead to inconsistency in results. For instance, some materials need fine grinding, while others are better processed coarsely. Choosing the right pulverizer can significantly enhance the quality of your samples.

Tips: Regular maintenance of pulverizers is essential. Clean your equipment regularly to avoid contamination. Also, calibrate your pulverizer frequently for optimal performance. Adjusting settings can help achieve the desired particle size. Stay informed about the latest advancements in pulverizing technology. This knowledge can guide your choice of equipment. Always consider the properties of the materials you work with; they influence the efficiency of the pulverizing process. Experimentation may reveal unexpected results.

Key Features to Consider When Choosing a Pulverizer

When selecting a laboratory sample pulverizer, several key features are essential. Speed and efficiency are among the top considerations. A machine that operates quickly can significantly save time in research. Look for models with adjustable speed settings. This flexibility allows customization based on sample type. Additionally, consider the capacity. A larger capacity is useful for bulk processing but may take up more space.

Another important aspect is the material of the pulverizer itself. A durable construction ensures longevity. Stainless steel is often preferred for its resistance to corrosion and ease of cleaning. Noise levels should also be evaluated. A quieter machine creates a better work environment, especially in shared spaces.

It's worth noting that not every pulverizer performs equally well with all sample types. Some may excel with certain materials and struggle with others. Users should test their samples with different machines to find the ideal match. Understanding the limitations can lead to improved outcomes in research. Remember to check for warranties and support from suppliers as well. These factors can enhance the overall experience and ensure you're equipped for future projects.

Top 10 Laboratory Sample Pulverizers to Enhance Your Research

This bar chart illustrates the performance ratings of the top 10 laboratory sample pulverizers, helping researchers choose the right model for enhancing their research capabilities.

Top 10 Laboratory Sample Pulverizers: A Detailed Review

Laboratory sample pulverizers play a crucial role in research and analysis. They help with reducing samples to a fine powder, necessary for accurate testing. The right pulverizer can significantly affect the quality of your results. Each type of pulverizer has unique features suited for various materials.

For example, some models excel at grinding hard materials, while others specialize in softer substances. This distinction is essential for researchers. You need to consider the sample type and desired particle size. A poorly chosen pulverizer could lead to inconsistent outcomes. It’s not just about the equipment; it’s also about user expertise and attentiveness.

A robust laboratory pulverizer should offer adaptability. Users might need to switch between sample types frequently. Not all models can handle this demand well. Some may falter under pressure, leading to frustration and wasted resources. Therefore, when selecting equipment, experience matters just as much as specifications.

Comparative Analysis of Performance and Efficiency

Pulverizers play a crucial role in sample preparation. Their efficiency directly affects research outcomes. A comparative analysis reveals significant differences among various models available today. For instance, studies indicate that high-speed pulverizers can achieve particle sizes as fine as 5 microns. This can enhance the accuracy of subsequent analyses.

However, performance is not solely about particle size. Energy consumption varies considerably between types. Some pulverizers consume up to 30% more energy than others in similar applications. This can impact the overall cost of research. When choosing a pulverizer, consider both performance and operational efficiency.

**Tip:** Always check for user reviews regarding operational noise. A loud machine can disrupt laboratory environments.

Moreover, maintenance is often overlooked. Regular maintenance can improve efficiency over time. Neglecting this aspect may lead to unanticipated downtime. Understanding your research requirements is essential. This helps in selecting the right equipment while minimizing costs.

**Tip:** Keep a maintenance log. This will help keep track of performance changes over time.

Tips for Proper Use and Maintenance of Pulverizers

Proper use and maintenance of laboratory sample pulverizers significantly enhance research quality. Having clean equipment is essential. Residue from previous samples can contaminate new ones. Always clean the pulverizer after each use. Use appropriate solvents for cleaning. Ensure no particles are left behind. This step is often overlooked, yet vital for accurate results.

Adjusting settings is equally important. Each material requires different settings. Failing to adjust could lead to poor sample quality. Take time to familiarize yourself with your pulverizer's features. Regularly check the blades and components. These parts can wear down over time, affecting performance. Neglecting maintenance can lead to costly repairs and inaccurate data.

Monitor operating conditions closely. Overworking the machine can cause overheating. This impacts the sample and the equipment's longevity. Keep a log of maintenance and usage. It helps track patterns and identify issues early on. Remember, meticulous attention to detail can prevent bigger problems later. Ensuring proper usage and maintenance is a continuous learning process. Reflection on these practices is key to successful outcomes in your research.

Top 10 Laboratory Sample Pulverizers to Enhance Your Research

| Rank | Pulverizer Type | Max Particle Size (mm) | Capacity (kg/h) | Power (W) | Weight (kg) |

|---|---|---|---|---|---|

| 1 | Planetary Ball Mill | 0.1 | 20 | 750 | 40 |

| 2 | Mortar Grinder | 1.0 | 5 | 300 | 15 |

| 3 | Disk Mill | 0.5 | 50 | 1000 | 36 |

| 4 | Ball Mill | 0.1 | 25 | 500 | 30 |

| 5 | Hammer Mill | 2.0 | 100 | 2000 | 50 |

| 6 | 316 Stainless Steel Grinder | 0.2 | 10 | 400 | 25 |

| 7 | Cryogenic Grinder | 0.1 | 15 | 600 | 35 |

| 8 | Blade Mill | 1.0 | 40 | 800 | 45 |

| 9 | Vibratory Mill | 0.07 | 15 | 650 | 28 |

| 10 | Pneumatic Mill | 2.5 | 75 | 1500 | 55 |